Company profile

SealCoat Auto Parts (Liaoning) Co., Ltd.

SealCoat Auto Parts (Liaoning) Co., Ltd. was established in April 1999. In 2015, it will build a new factory area in Dalinghe Industrial Park, Linghai City, with a construction area of nearly 50000 square meters and an actual floor area (about 170 mu). It has built a painting workshop, flocking workshop, injection molding workshop, mold workshop, assembly workshop, logistics storage center, office building, canteen, dormitory, research and development center, with a total construction area (46950.59) and office building area (5234.13), the workshop area (36839.02) is flat.

SealCoat Auto Parts (Liaoning) Co., Ltd. has six production bases in Jinzhou, Liaoning, Foshan, Guangdong, Jiaxing, Zhejiang, Hefei, Anhui, Changchun, Jilin and Tianjin. Specializing in the design, development and production of automotive interior parts, and the design, development and processing of molds, it has now formed an integrated business model of automotive interior design, mold design and processing, injection molding, spraying, flocking, and assembly production. Product distribution FAW-Volkswagen, Mercedes-Benz, BMW, Hongqi, Toyota and many other OEMs. Our company has obtained IATF 16949:2016 automobile industry quality management system standard, ISO14001:2015 environmental management system certification, ISO45001:2018 occupational health and safety management system certification. And won the pilot unit of Liaoning Province's intellectual property project of "Xingye Strong Enterprise"; 2014-2016 Liaoning Province Private Economy Statistics Advanced Collective Honorary Title; "Auto Interior Trim" was awarded the 2017 Liaoning Brand Product; In 2019, the "robot automatic flocking system" was rated as the "specialized and special new" product of small and medium-sized enterprises in Liaoning Province. Provincial Enterprise Technology Center in 2020; In 2020, "Volkswagen Q5 car glove box connecting rod lock mechanism" is "; in 2021," flocking technology "is a" specialized and special new "product technology. 2021 review won the" high-tech enterprise "; In 2022, it won the title of" Little Giant "," Modern Service-oriented Manufacturing Demonstration Enterprise ", UV Workshop won the title of" Digital Workshop "for the Provincial Intelligent Manufacturing and Strong Province Project, and in 2022, it won the title of" Liaoning Provincial Staff Innovation Studio "awarded by the Provincial Federation of Trade Unions. SealCoat Auto Parts (Liaoning) Co., Ltd. has a total of 31 patents, 5 inventions, and 26 utility models; 21 utility model patents in Foshan; Zhejiang company has 29 patents, 1 invention, and 19 utility models!

SealCoat Auto Parts (Liaoning) Co., Ltd. has been continuously improving its R & D and manufacturing capabilities, inspection and testing capabilities for many years, and now has:

Mold development: 35 sets of CNC, EDM, WEDM, machining and other complete sets of manufacturing equipment involved in mold development can meet the integrated design, development and manufacturing of automotive interior molds;

44 injection molding machines, of which precision injection molding and two-color injection molding accounted for 15%;

3 automatic flocking production lines, 45 automatic production group;

5 spraying production lines, including 3 automatic spraying lines;

Assembly production line 15. It covers assembly ultrasonic welding, hot plate welding machine, infrared welding machine, hot riveting welding machine and other processes. At the same time, the company has a complete set of cladding production lines such as design shearing, sewing, spraying, wrapping and activation.

Inspection and testing: R & D laboratory has a material laboratory, functional laboratory, with domestic and foreign advanced CMM measurement system, blue light scanning system, combustion tester, Emission analysis, etc., the laboratory has more than 50 sets of various experimental equipment;

SealCoat Auto Parts (Liaoning) Co., Ltd. has been committed to product development and technology transformation since its establishment. The Technology Research and Development Center has a project department, which sets up corresponding project managers according to different OEMs, formulates development plans and strictly monitors and manages project progress to ensure the smooth progress of project development. At the same time, the Sealcoat project management and control process is improved, including the project manager resource allocation mechanism, the expansion of horizontal functional group mechanism, the periodic review and release mechanism, the emergency plan and the delay prevention mechanism. According to the requirements of customers, the new project can successfully complete various development work, modeling concept design and external surface smooth design, vehicle perceived quality improvement, vehicle section design scheme, internal and external decoration structure design and development, vehicle CAE analysis and environmental simulation, size management and GD & T. After years of continuous efforts to innovate, a total of 29 patents have been applied, and all of them have been put into use in the company's manufacturing process. Sealcoat has been well received by domestic and foreign OEMs in research and development, quality assurance, supply and other aspects.

2021 is the first year of the 14th Five-Year Plan. In response to the call of the country for high-quality development, our company established the "Sealcoat Environmental Protection Intelligent Factory System" in 2021 and started the digital transformation of the factory. According to the actual situation of the company, we cooperated with the software development company to customize MES production and manufacturing execution system software in line with Hilda's current situation, purchase UV high-gloss automatic spraying production line, and develop the fifth generation full-automatic environmental protection flocking line, the total investment of the project has been 23 million since 2021, and the transformation of the digital workshop is still in progress.

Under the guidance of new national plans and new policies, our company has discovered a new track-new energy vehicles with a keen market sense. In January 2022, a new factory will be established in Hefei, Anhui Province, mainly to develop new energy vehicles. The promotion of new energy vehicles will surely drive the reengineering of the entire parts industry, giving Sealcoat a greater development opportunity. Now Sealcoat is cooperating with new concept energy vehicle factories such as Weilai, Ideal, Weima and Xiaopeng on the basis of existing cooperative brands. Broaden the market, increase the market share of products, and enhance the competitiveness of the new economic environment.

In 2023, SealCoat Auto Parts (Liaoning) Co., Ltd. is constantly improving the level of intelligence and automation in the automotive industry. Our company has developed new market areas-automotive electric functional products, such as: car armrests, Seat heating, seat SBR sensor. While meeting the new needs of customers, it is also committed to the trend and trend of intelligent and automated development of automotive interior functional parts.

Qualification Honor

Liaoning Province's Manufacturing Single-Champion Enterprises

Jinzhou City May Day Labor Award Certificate

Jinzhou City Quality Infrastructure "One-Stop" Service Workstation

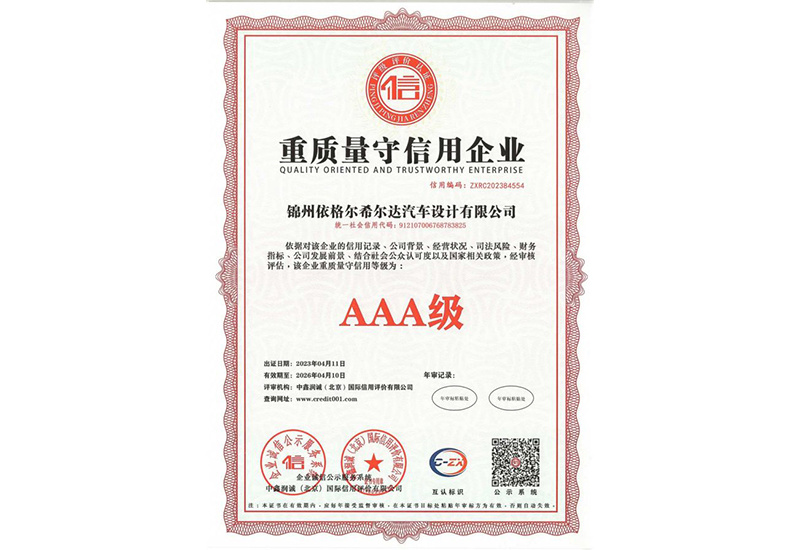

Jinzhou Yigeer is a quality-oriented and creditworthy enterprise (3A).